This drilling string design program is a unique course discussing all factors that influence the drill string during operations. By the end of this PetroKnowledge online training course participants will be able to.

Drill String Design Course.

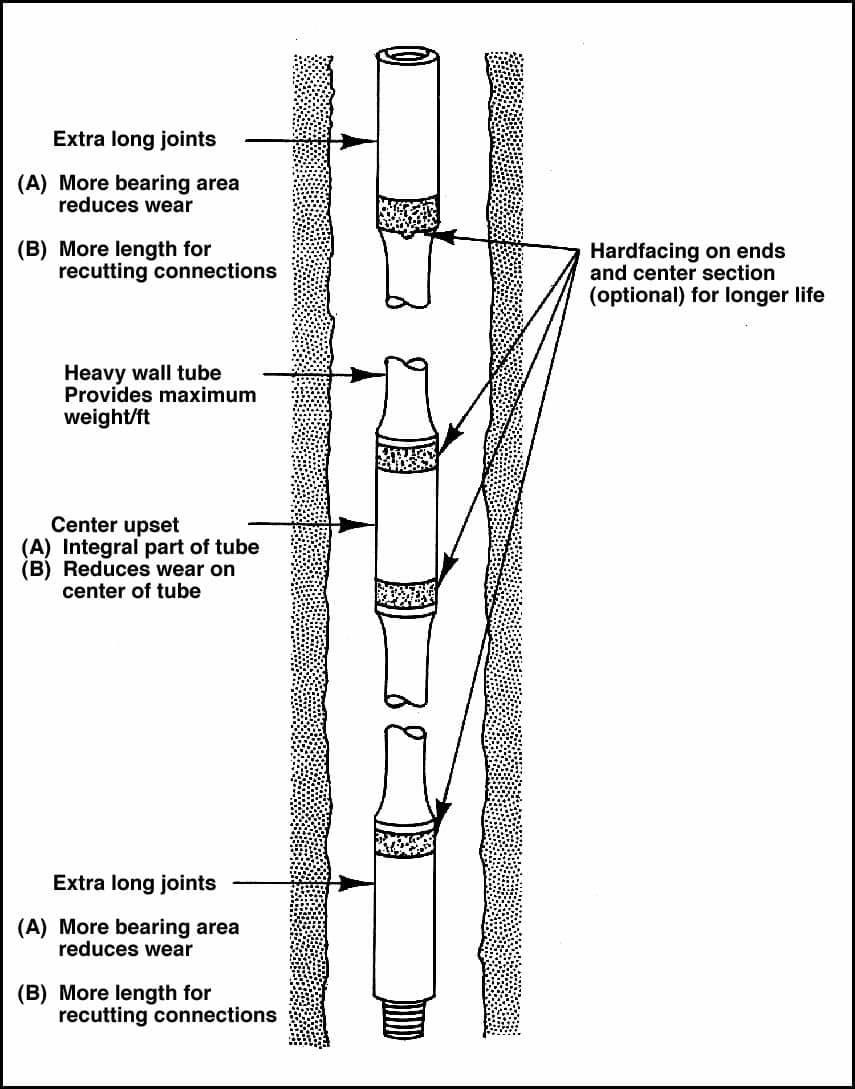

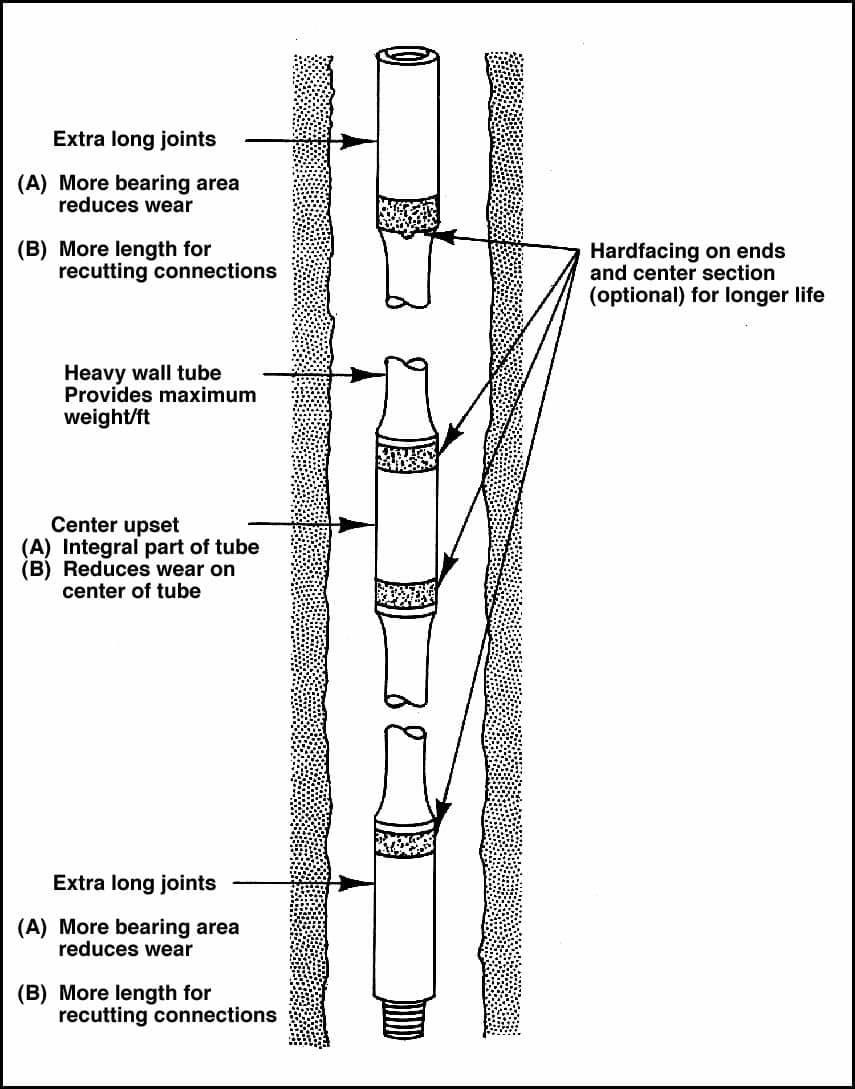

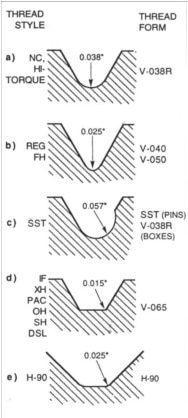

. Hole depth hole size mud weight safety factor andor margin of pull length and weight of DCs drill pipe. Drill String Design Drill String Failure Prevention Stuck Pipe Prevention NS-1 NS-2 ISO 90012015 Spec Q1 API Q2 API E. Drill string design Design means determination of length weight grades of drill pipe to be used during drilling coring or any other operation Depends on.

Design bits for specific applications and optimal performance. This is a three day course designed to take Engineers up to the level where they can confidently perform a hand calculation based design of a drill string. BHA design concepts are investigated with emphasis on practical engineer.

Design drill string and BOP wellheads Design and implement bit and hydraulics programs. Written by specialist drilling engineers it will assist in your drill string design for a particular. Pair the bit and motor to improve motor and bit life and overall performance.

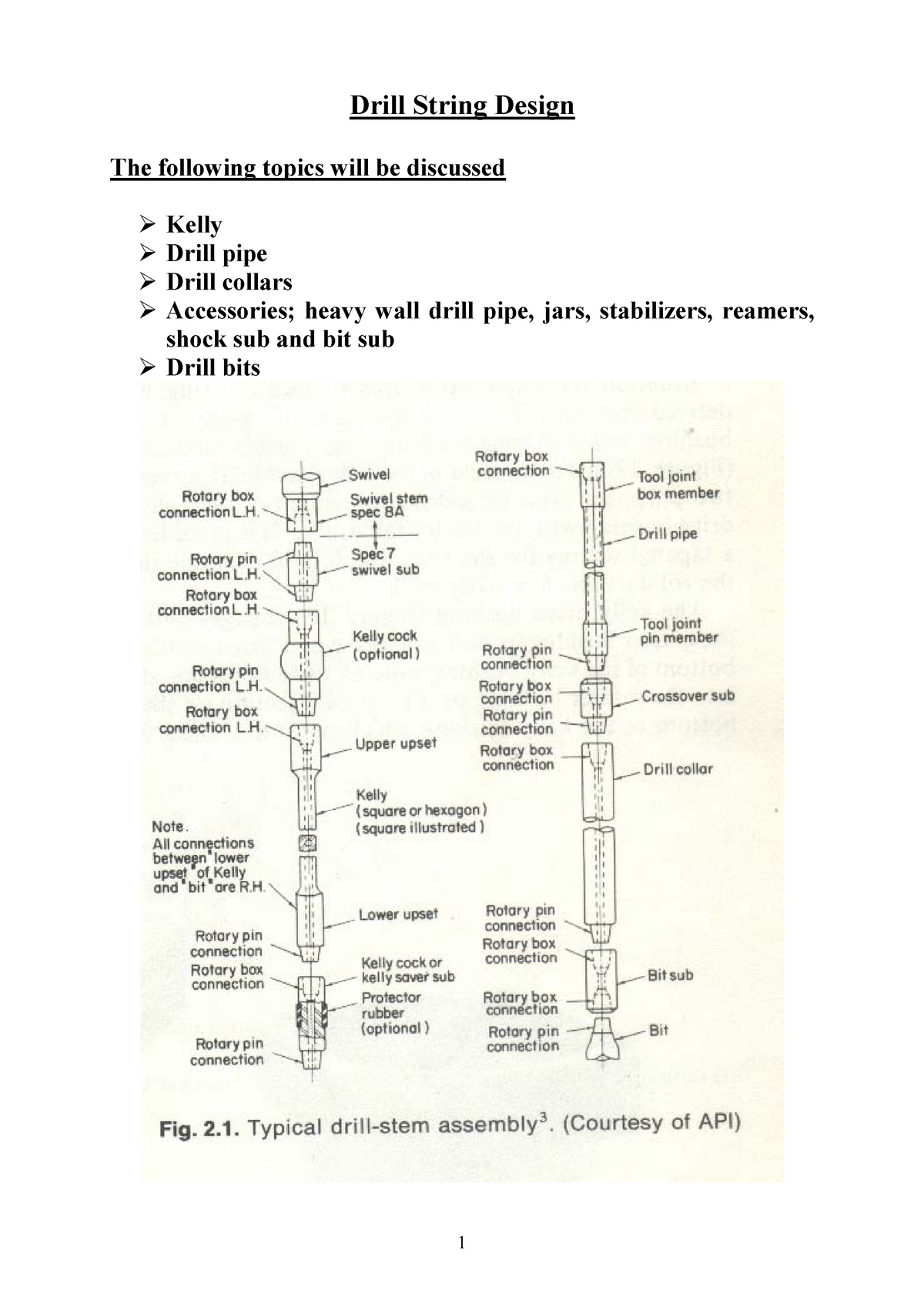

The participants will learn about the drill pipe grade the limitation for torque and tension and the drill collars tensional stress. This course is divided into 5 sections as follows. The moving fluid cools and lubricates the bit and removes the rock cuttings that would otherwise collect at the bottom of the wellbore.

The course is intended to provide drilling and well engineers with the competency to design a drillstring for a well. DST considerations torque and drag calculations. The drill pipe constitutes the majority of the drill string length.

In case you are a colorful girl Then you can certainly consider up brighter color tones to your nails if you like delicate points so obviously your mood will pick up on nail paints which can be a bit uninteresting and fewer flashy. The drill pipe has two tool joints one female is called a box and the other male is called pin. There are four basic types of drilling fluids used in New York State.

Initiation to WellScan Software Platform. It is seamless with threaded connections. Topics covered include vertical and deviated well string design selection of BHA to provide the required WOB.

It refreshes hidden physics of drill string failures and mechanical properties of drill string materials. Drill string design for directional and horizontal wells. The fundamental pendulum assembly increases the restoring force by increasing the pendulum length with a stabiliser in the proper position.

The course provides a comprehensive treatment of drill string design as well as the avoidance of operational problems and wear on equipment following the API recommended practices for design and operating limitations as well as the standard DS1 for design and inspection. Using both vertical and directional well profiles participants are taken through the design of a drillstring for various scenarios using current design standards. Find the optimal drill bit for your drilling interval no matter how challenging.

Drill String Design The course is designed for drilling operational staff and drilling engineers. Stuck point calculations for drill string weight jar placement. Torque and tensile loads can be modelled accurately for a range of load cases that are expected within the given well operation using torque and drag software.

1st 2nd sessions. The Drill String Design Manual has been produced to assist engineers in the selection design and placement of the appropriate components within a drill string. Drill string design methods.

Drill string design course Nail artwork inspires Everybody. This allows components to be specified such that the applied load remains below the rated load with some reserve capacity built in for use in an emergency. This 5-day course will address all elements of drillstring selection and design integrating drilling optimisation with drillstring failure prevention.

Various operational loads and limits discussed will provide more comprehensive view of the drillstring mechanics. Routine Torque. The outer diameter of the tool joint is larger than the body of the drill pipe to accommodate the threads.

We have been presenting Drill String Design workshops for over 12 years for all types of operations around the world. The drillstring design is completed from first principles and using spreadsheets so that. Drill collar weight and neutral point.

The course provides a comprehensive treatment of drill string design downhole drilling dynamics and the avoidance of operational problems and wear on equipment following the API recommended practices for design and operating limitations as well as the standard DS1 for. For a drillstring of constant cross section the resulting hook load can be calculated as follows. It clarifies the performance properties of drill string components and explains how to apply design margins.

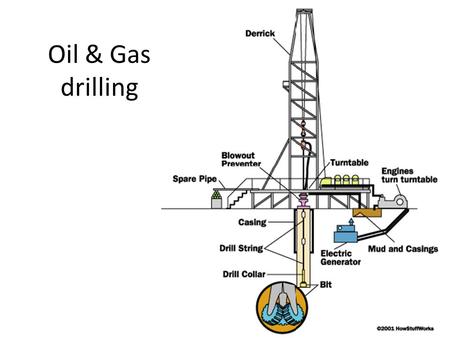

Drill string design process is placed in context with other planning and operational considerations of well planning. Fluids are pumped down the drill string out through holes jets in the drill bit and up the wellbore. The concept of drill-string design is well understood.

The course provides a comprehensive treatment of drill string design as well as the avoidance of operational problems and wear on equipment following the API recommended practices for design and operating limitations as well as an overview of. Air freshwater brine and mud. By combining these skills into focused training programs fearnley Procter has become acknowledged as a global leader in this specialist training field.

The course provides a comprehensive treatment of drill string design practices with theoretical underpinnings. 29 29 HL WT x D CSA x x MW x D HL Hookload lbf WT Weight of drillstring lb ft D Depth of well ft CSA Cross tional area of drillstring wall in MW Mud weight ppg string string string string - - 0 052 2 sec Buoyancy acting at the bottom of the drillstring places the lower portion of. This will give a good understanding in interpreting the outputs of torque and drag software.

We are constantly updating our materials to reflect the latest technology applications for both near-vertical and high-angle well designs while maintaining a thorough grounding in the fundamentals. Drill a well cost effectively and maximize penetration rate Evaluate stuck pipe problems and avoid potential problems by optimizing hole cleaning and ROP. When the drillstring is lowered into the borehole the total length of the drillstring is under tension due to its own weight which is partly counterbalanced by the buoyancy.

Minimize vibrations and stickslip during drilling operations and optimize BHA performance for a given environment. Taking into consideration the environment and the stresses and strains that the drill string will be required to operate under. Participants will learn about the mechanical properties of all drillstring components including their connections both as individual pieces and when made up into a drillstring.

Specialised training to reduce Non-Productive Time is our core business.

Drill String Design Lecture Notes 12 45 Studocu

Bottom Hole Assembly Bha Components And Design Drilling Manual

Basic Drilling School Course Objectives During This Drilling School You Will Get All The Knowledge About Drilling Oil And Gas Wells Design Requirements Ppt Download

Drill String Design Calculations Complete Guide Drilling Manual

Drill String Design Calculations Complete Guide Drilling Manual

Basics Of Drill String Design Skillsupload

The Drill String Vibration And Shock Modes In Typical Well Download Scientific Diagram

0 comments

Post a Comment